Managing multiple contractors for individual projects can be stressful and costly. Partner with SVI Industrial for all of your industrial maintenance and welding needs to reduce your workload and costs by working with one point of contact for your entire project. We Hold NBIC “R” and ASME Section I Certifications. Contact us for your next project.

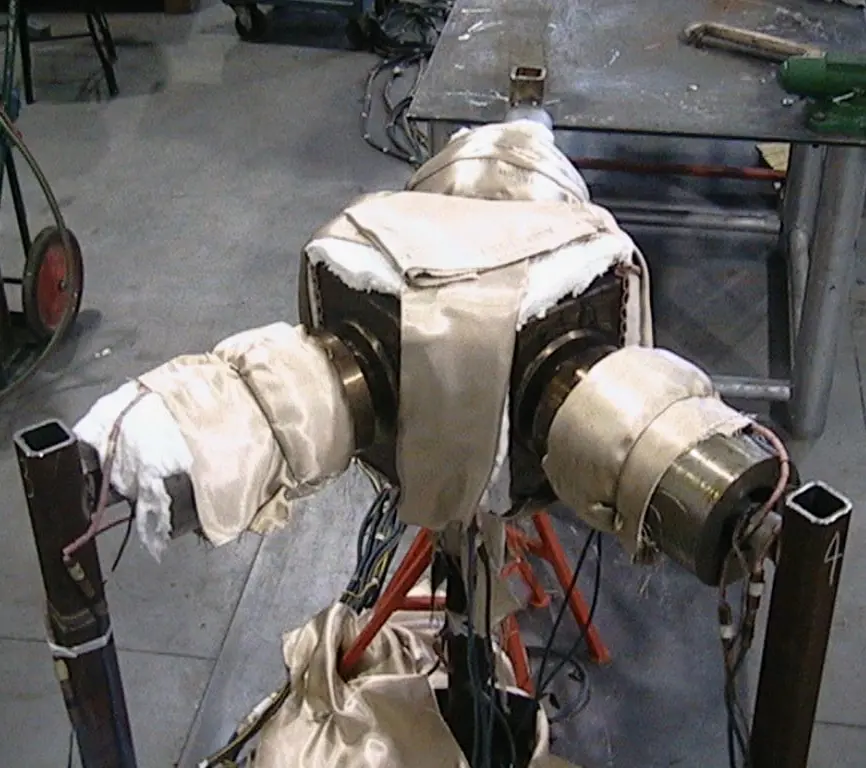

SVI BREMCO offers a variety of field welding and installation services. These services include NBIC “R” repairs, API tank repairs, high-pressure valve installation, heavy wall carbon/chrome alloy / P91 welding, fabricated pipe and vessel installation, in-situ valve seat hardfacing and various other alloy welding services.

SVI BREMCO is well qualified to perform your next project.

SVI BREMCO is well qualified to perform your next project. We Hold NBIC “R” ASME Section I, and ASME Section VIII Div.1 Certifications. All welding procedures and welder qualifications are performed in accordance with ASME Section IX. Our team of welders and engineers are committed to quality, efficiency, and reliability in order to provide you with the most innovative and outstanding service in the industry. We utilize a quality system that meets the highest industry standards.

At SVI BREMCO, our certified welding technicians and professional engineers are committed to delivering quality workmanship and outstanding service that is unparalleled in the industry. Because of the wide range of specialty welding services we offer, we are truly your one-stop shop for all your industrial maintenance needs, including fabrication and field welding, vessel and piping design and installation, custom machining, valve repair, and other engineering services. Because of our wide-ranging services, you can leverage our expertise to deal with a single point of contact for your entire project and save on workload, project cost and ultimately cost of operations.

SVI BREMCO’s on-site welding and fabricating services include:

- Installation of jacketed and unjacketed piping assemblies

- Installation of bolt-on pipe heating systems

- On-site repair and modifications of code-stamped heat exchangers and code vessels

- Carbon Steel, stainless steel, nickel-alloy and titanium pipe installation

- API tank repairs

- In-situ CoCr “Stellite” and other hard facing valve overlays

- Inline Valve installation and replacement

- Confined space welding

- On-site exhaust stack repairs, installation and modification

- Welding, fabrication and install of piping assemblies

- Custom design and engineering of piping systems

Our unique ability to combine our welding expertise with our cutting-edge field machining capabilities enables us to be a turnkey provider, ultimately increasing the efficiency of your plant and reducing your downtime.